Market research shows that today’s consumers are increasingly interested in knowing where their food comes…

Cutting It Too Fine

Modern slaughter facilities—especially smaller operations—can face significant challenges when attempting to provide an efficient service to their customers. By understanding the most common challenges that plants may experience, farmers and ranchers can help improve efficiencies at slaughter facilities—and avoid unnecessary delays and costs.

Slaughter plant challenges

Running a slaughter facility can be financially challenging, particularly for small-scale operations with high overhead costs, including equipment, maintenance and labor, and regulatory compliance. All slaughter facilities must comply with copious regulations and standards set by government agencies, such as the USDA, requiring significant time, training and ongoing financial investments, while fluctuating market prices can make profitability uncertain.

As you might expect, ensuring food safety is critical for slaughter facilities. They must implement stringent procedures and protocols to prevent contamination and the spread of foodborne illnesses, with a regimen of regular testing and equipment inspection. And that’s before we consider the actual day-to-day work involved in one of the most stressful and dangerous aspects of meat production.

The work environment is physically demanding and potentially dangerous, requiring specialized training and experience. As a result, finding and retaining skilled labor can be very challenging, particularly in rural areas or regions with limited workforce availability.

AGW-reviewed slaughter facilities must prioritize animal welfare, with proper handling to minimize stress, requiring significant training to ensure humane handling and treatment throughout the process. Like farms, slaughter facilities must also address the environmental concerns associated with effluent discharge and animal by-products. As we all know, implementing sustainable practices and adhering to environmental regulations can be costly and require ongoing monitoring and mitigation efforts.

It is in the mutual interest of every farmer and rancher to ensure the future viability of local, high-welfare slaughter infrastructure for the benefits of animal welfare AND the viability of their own businesses. So, as customers of slaughter plants, what steps can we individually take to help minimize disruption and improve efficiencies for these essential business partners?

Scheduling

Most slaughter facilities schedule animals anywhere from three to 18 months out, so early and regular communication with your facility is paramount to ensure your product is available when you need it.

Once you are scheduled in, it is absolutely essential to notify the plant as soon as possible if any circumstances change—including changes in slaughter weight, mortality, and market demand—that make it necessary to cancel. This allows them to fill the slot.

Arriving on time with the animals clean and in appropriate condition is also very important, as most facilities start early in the morning. Should you arrive late, remember slaughter employees get the same pay per hour whether you are on time or late. Similarly, cooler space is often limited, particularly at smaller facilities, and requesting longer hang times without notice creates storage issues. Think how much cooler space a plant that slaughters 20 beef a day, five days per week, would need to hang carcasses for up to 28 days.

Cut instructions

To ensure the plant has a clear idea of what cuts you want, most operators will supply a cut sheet in advance. Yet many customers have false expectations about the quantity (and sometimes quality) of meat they will receive from their animal.

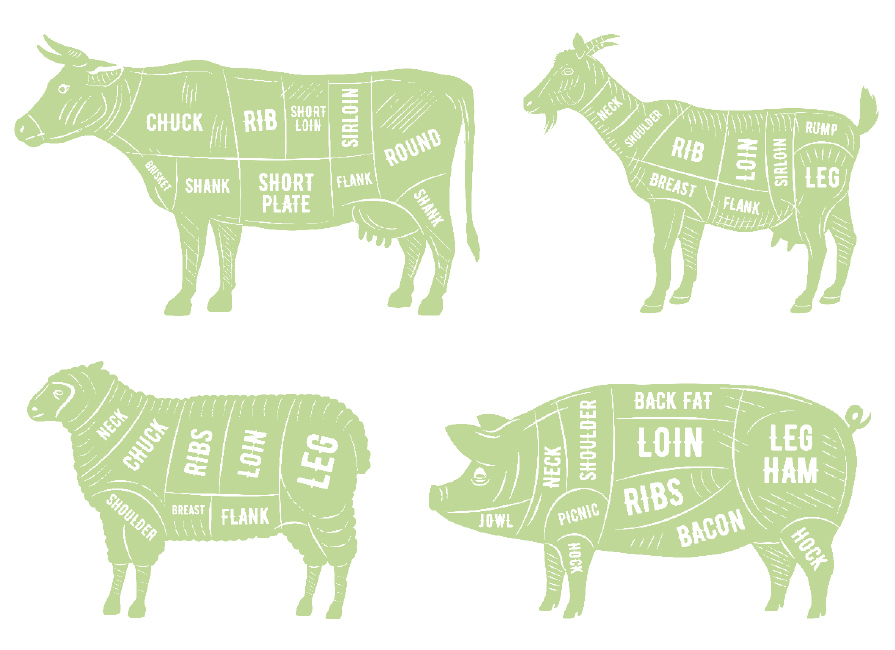

A general rule for beef is that after the head, hide, feet, blood, and viscera (internal organs) are removed, the carcass will weigh 50% to 60% of the live weight. This is called ‘hanging weight’. The amount of hanging weight is influenced by many factors, such as age, muscle score, genetics, amount of fill, clean vs dirty hide, and so on. Depending on the cuts ordered, you may lose anywhere from 30% to 50% of the hanging weight during processing into final cuts.

Pigs typically have a hang weight of 72% of liveweight and approximately 48% of liveweight for final cut. The final weight depends on size, age, breed, and if skinned or dehaired. Sheep and goats typically have a hang weight of 50%-58% of liveweight and 37% to 40% of liveweight for final cut, again depending on age, breed, grassfed versus grain-fed and so on.

Once the carcass is cut and packaged, the producer will receive anywhere from 400-600 lbs. of packaged meat. The amount greatly depends on what cuts are wanted; ground beef, roast, ribs, or steaks, and the age of the animal. Bovine spongiform encephalopathy (BSE) regulations require the removal of the backbone from animals over 30 months, thus eliminating T-bone, porterhouse, and some rib cuts.

A recurring issue arises when meat does not meet the farmers’ expectations, with some farmers insisting they did not receive meat from their animals or even accusing plant workers of shortchanging meat. Remember that most plants now have a highly traceable inventory systems to ensure the animal brought in is the meat going out.

Collecting the final cut product in a timely manner is equally important, as freezer space is a premium. Delays in picking up meat will require additional freezer space and energy to maintain the frozen meat. Remember to ensure you have sufficient space and equipment to safely transport and store the meat for your customers. Contact the facility if you need any advice.

Labeling

When it comes to labeling your packaged meat, the facility (and you) must comply with numerous regulatory requirements.

The labeling process is sometimes protracted, so it is important to contact the plant facility well in advance and inquire what labeling services they can offer and, if appropriate, what information the facility needs from you. Some facilities may only offer a basic statutory labeling service, or they may require a specific type of label for their machines. You may find that you need to get your packaging labels designed and printed elsewhere, or even apply them yourselves after you collect your packaged meat.

Understanding the challenges that slaughter plants face—and how we can help minimize disruptions and delays as customers—will help to ensure these vital facilities remain available to support the development of the sustainable livestock sector for the future.

USING YOUR AGW LOGO

AGW’s new traceability standards require producers to display the relevant AGW logo(s) on all certified products, unless agreed with AGW. The new rules also require producers to ensure their labels are in compliance with the guidelines and are approved by the program.

AGW’s marketing team offers a label design service at no cost to certified businesses. Find out more at agreenerworld.org/farmer-services/labeling-support/.

Author: Charlie Hester is Lead Slaughter Specialist at A Greener World

Originally published in the Fall 2023 issue of AGW’s Sustainable Farming magazine.